- We grow crystal material to your need.

- We polish and coat to high LDT.

- We stock material to control price and delivery.

- We offer failure analysis FREE.

- Uniform rods suplly, minimal rejection ratio.

Arsuf lasers offers competitive production capability and crystal growth for laser rods/slabs, in particular Erbium doped glass. Our standard polish and hard-coating result in very high Laser Induced Damage (LIDT) compared to others. The Erbium and Ytterbium co-doped phosphate glass is the best glass material for 1.54μm laser due to its eye safe wavelength of 1540 nm and high transmission through the atmosphere.

However, this phosphate is highly temperature- sensitive, turning high spec polishing into a skilled mission. The phosphate is also hygroscopic, affecting the coating’s life expectancy. In the process of providing thousands of erbium rods to clients worldwide, we developed a controlled process. We offer prototyping at no risk and charge upon success only. The material can either be grown by us to spec or duplicated from materials in use.

Erbium rods include rare earth element Er3 + as the active ion in various type of matrixes such as:

YAG, YAP, YLF (LiYF4), YSGG and glass

Application INCLUDEs:

- Eye-safe laser range finder (LRF) and Telemetry

- Optical fiber communication

- 1470nm and 1532 nm Pumping

- Hair Removal Cosmetics

- 2940 µm Er:YAG Medical Laser Systems and Dental Laser Systems

Er,Yb,Cr:Glass ROD SPECS

- Parallelism: 1-5 arc seconds

- Perpendicularity: 1-5 arc minutes

- Surface Quality 10/5

- Laser Damage Threshold: 25-50 J/cm2, 10ns, 10Hz

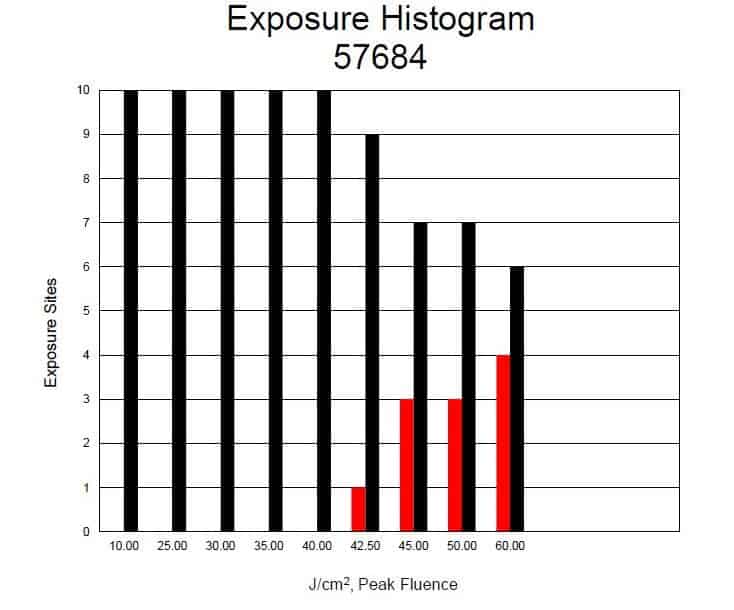

HIGH LASER DAMAGE THRESHOLD A/R COATING

Withstands 40.00 j/cm2 @ 1540nm 8ns pulses (Er,Yb:YAG)

Testing Provided By: SPICA Technologies, Inc.

Products & Services

About Us

The company was founded in 2008.

Arsuf Lasers offers extensive support to multinational companies operating across the world,

by staffing dedicated support engineers.

Laser rod is a key optical element for laser range finder (LRF),

medical laser systems and cosmetic laser machines.

Aesthetic applications are in dermatology, ranging from hair removal to photorejuvenation,

vascular and acne treatment, tattoo removal and treatment of visible leg veins

and pigmented lesions.

We have many years of experience and capability to design custom laser rods,

from growing the material up to the final hard coating,

optimized to your special laser and at reasonable price,

from prototype to large volume quantity.

Avi Schiff, the company chief engineer with many years of experience and knowledge,

is well-known to R&D Groups and leads his field technical staff to

long term successful contracts.

Avi Schiff

I am the founder and senior technical director of Arsuf Lasers, specializing in the supply of high-spec, hard-to-find components and modules for lasers.

Focusing over the years as a laser engineer on laser interaction with materials, I mastered new topics ranging from pulsed laser deposition, growth of materials, and robust LIDT coating. Serving the high-end laser application industry is my goal.

Thanks to more than 30 years of industrial and R&D experience, refining my craft and nurturing crucial connections with local and international partners, I can deliver optimal solutions for all client requirements.